What is sourdough bread

Sourdough bread is made by the fermentation of dough using naturally occurring lactobacilli and yeast 1. Sourdough bread has a mildly sour taste not present in most breads made with baker’s yeast and better inherent keeping qualities than other breads, due to the lactic acid produced by the lactobacilli.

Sourdough is a dough containing a Lactobacillus culture in symbiotic combination with yeasts. It is one of the principal means of biological leavening in bread baking, the others using cultivated forms of yeast. It is important in baking rye-based breads, where yeast does not produce comparable results 2.

One of the oldest sourdough breads dates from 3700 BC and was excavated in Switzerland, but the origin of sourdough fermentation likely relates to the origin of agriculture in the Fertile Crescent several thousand years earlier. Bread production relied on the use of sourdough as a leavening agent for most of human history; the use of baker’s yeast as a leavening agent dates back less than 150 years 3. Sourdough remained the usual form of leavening down into the European Middle Ages until being replaced by barm from the beer brewing process, and then later purpose-cultured yeast 4.

Bread made from 100% rye flour, popular in the northern half of Europe, is usually leavened with sourdough. Baker’s yeast is not useful as a leavening agent for rye bread, as rye does not contain enough gluten. The structure of rye bread is based primarily on the starch in the flour, as well as other carbohydrates known as pentosans; however, rye amylase is active at substantially higher temperatures than wheat amylase, causing the structure of the bread to disintegrate as the starches are broken down during cooking. The lowered pH of a sourdough starter, therefore, inactivates the amylases when heat cannot, allowing the carbohydrates in the bread to gel and set properly 5. In the southern part of Europe, where panettone was originally made with sourdough, sourdough has become less common in recent times; it has been replaced by the faster-growing baker’s yeast, sometimes supplemented with longer fermentation rests to allow for some bacterial activity to build flavor.

French bakers brought sourdough techniques to Northern California during the California Gold Rush, and it remains a part of the culture of San Francisco today. Sourdough has long been associated with the 1849 gold prospectors, though they were more likely to make bread with commercial yeast or baking soda 6. The San Francisco sourdough is a white bread characterized by a pronounced sourness, and indeed the strain of lactobacillus in sourdough starters is named Lactobacillus sanfranciscensis, alongside the sourdough yeast Candida milleri found in the same cultures 2.

Sourdough is a stable culture of lactic acid bacteria and yeast in a mixture of flour and water. Broadly speaking, the yeast produces gas (carbon dioxide) which leavens the dough, and the lactic acid bacteria produces lactic acid, which contributes flavor in the form of sourness. The lactic acid bacteria metabolize sugars that the yeast cannot, while the yeast metabolizes the byproducts of lactic acid fermentation. The most common yeast species in sourdough are Kazachstania exigua (Saccharomyces exiguous), Saccharomyces cerevisiae, Candida milleri, and Candida humilis 7.

Table 1. Sourdough bread nutrition facts

Nutrient | Unit | SLICE 49 g | Value per 100 g | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approximates | |||||||||||||||||||

| Energy | kcal | 120 | 245 | ||||||||||||||||

| Protein | g | 4.00 | 8.16 | ||||||||||||||||

| Total lipid (fat) | g | 1.50 | 3.06 | ||||||||||||||||

| Carbohydrate, by difference | g | 23.00 | 46.94 | ||||||||||||||||

| Fiber, total dietary | g | 1.0 | 2.0 | ||||||||||||||||

| Sugars, total | g | 0.00 | 0.00 | ||||||||||||||||

| Minerals | |||||||||||||||||||

| Calcium, Ca | mg | 40 | 82 | ||||||||||||||||

| Iron, Fe | mg | 1.44 | 2.94 | ||||||||||||||||

| Sodium, Na | mg | 230 | 469 | ||||||||||||||||

| Vitamins | |||||||||||||||||||

| Vitamin C, total ascorbic acid | mg | 0.0 | 0.0 | ||||||||||||||||

| Vitamin A, IU | IU | 0 | 0 | ||||||||||||||||

| Lipids | |||||||||||||||||||

| Fatty acids, total saturated | g | 0.000 | 0.000 | ||||||||||||||||

| Fatty acids, total trans | g | 0.000 | 0.000 | ||||||||||||||||

| Cholesterol | mg | 0 | 0 | ||||||||||||||||

Ingredients: ENRICHED FLOUR (WHEAT FLOUR, MALTED BARLEY FLOUR, NIACIN, REDUCED IRON, THIAMIN MONONITRATE, RIBOFLAVIN, FOLIC ACID), WATER, YEAST, WHEAT GLUTEN, CONTAINS LESS THAN 2% OF SOYBEAN OIL, SUGAR, SODIUM STEAROYL LACTYLATE, SALT, FURMARIC ACID, DATEM, DEXTROSE, SODIUM DIACETATE, LACTIC ACID, SILICON DIOXIDE, ASCORBIC ACID, ENZYMES.

[Source: United States Department of Agriculture Agricultural Research Service 8]Types of sourdough bread

There are many breads that use techniques similar to that used in the making of sourdough bread. Danish rugbrød (rye bread) is a dense, dark bread best known from its use in the Danish smørrebrød (open-faced sandwiches) 9. Amish friendship bread uses a sourdough starter that includes sugar and milk. It is also leavened with baking powder and baking soda. An Amish sourdough is fed with sugar and potato flakes every 3–5 days. German pumpernickel is traditionally made from a sourdough starter 10, although modern pumpernickel loaves often use commercial yeasts, sometimes spiked with citric acid or lactic acid to inactivate the amylases in the rye flour. Flemish desem bread (the word means ‘starter’) is a whole-wheat sourdough 11. In Azerbaijan, whole-wheat sourdough flatbreads are traditionally eaten 12. In Ethiopia, teff flour is fermented to make injera 13. A similar variant is eaten in Somalia, Djibouti, and Yemen (where it is known as lahoh) 14. In India, idlis and dosa are made from a sourdough fermentation of rice and vigna mungo 15.

Figure 1. Sourdough bread

Type I sourdough

Traditional San Francisco sourdough is a Type I sourdough 16. Type I sourdoughs are generally firm doughs 17, have a pH range of 3.8 to 4.5, and are fermented in a temperature range of 20 to 30 °C (68 to 86 °F). Lactobacillus sanfranciscensis was named for its discovery in San Francisco sourdough starters, though it is not endemic to San Francisco. Lactobacillus sanfranciscensis and L. pontis often highlight a lactic-acid bacterial flora that includes L. fermentum, L. fructivorans, L. brevis, and L. paralimentarius 18. The yeasts Saccharomyces exiguus, Candida milleri, or Candida holmii 16 usually populate sourdough cultures symbiotically with Lactobacillus sanfranciscensis 19. The perfect yeast S. exiguus is related to the imperfect yeasts C. milleri and C. holmii. Torulopsis holmii, Torula holmii, and S. rosei are synonyms used prior to 1978. C. milleri and C. holmii are physiologically similar, but DNA testing established them as distinct. Other yeasts reported found include C. humilis, C. krusei, Pichia anomaola, C. peliculosa, P. membranifaciens, and C. valida 20. There have been changes in the taxonomy of yeasts in recent decades 21. L. sanfranciscensis requires maltose 22, while C. milleri is maltase negative and thus cannot consume maltose 23. C. milleri can grow under conditions of low pH and relatively high acetate levels, a factor contributing to sourdough flora’s stability 24.

In order to produce acetic acid, L. sanfrancisensis needs maltose and fructose 25. Wheat dough contains abundant starch and some polyfructosanes, which enzymes degrade to “maltose, fructose and little glucose” 26. The terms “fructosan, glucofructan, sucrosyl fructan, polyfructan, and polyfructosan” are all used to describe a class of compounds that are “structurally and metabolically” related to sucrose, where “carbon is stored as sucrose and polymers of fructose (fructans)” 27. Yeasts have the ability to free fructose from glucofructans which compose about 1–2% of the dough. Glucofructans are long strings of fructose molecules attached to a single glucose molecule. Sucrose can be considered the shortest glucofructan, with only a single fructose molecule attached 28. When L. sanfrancisensis reduces all available fructose, it stops producing acetic acid and begins producing ethanol. If the fermenting dough gets too warm, the yeasts slow down, producing less fructose. Fructose depletion is more of a concern in doughs with lower enzymatic activities 5.

A Belgian study of wheat and spelt doughs refreshed once every 24 hours and fermented at 30 °C (86 °F) in a laboratory environment provides insight into the three-phase evolution of first-generation-to-stable sourdough ecosystems. In the first two days of refreshment, atypical genera Enterococcus and Lactococcus bacteria highlighted the doughs. During days 2–5, sourdough-specific bacteria belonging to the genera Lactobacillus, Pediococcus, and Weissella outcompete earlier strains. Yeasts grew more slowly and reached population peaks near days 4–5. By days 5–7, “well-adapted” Lactobacillus strains such as L. fermentum and L. plantarum had emerged. At their peaks, yeast populations were in the range of about 1–10% of the lactobacilli populations or 1:10–1:100. One characteristic of a stable dough is that the heterofermentative have outcompeted homofermentative lactobacilli 29.

Investigations of wheat sourdough found that S. cerevisiae died off after two refreshment cycles 28. S. cerevisiae has less tolerance to acetic acid than other sourdough yeasts 30. Continuously maintained, stable sourdough cannot be unintentionally contaminated by S. cerevisiae.

Type II sourdough

In Type II sourdoughs, baker’s yeast or Saccharomyces cerevisiae 31 is added to leaven the dough; L. pontis and L. panis highlight the flora 32. They have a pH less than 3.5, and are fermented within a temperature range of 30 to 50 °C (86 to 122 °F) for several days without feedings, which reduces the flora’s activity 33. This process was adopted by some in industry, in part, due to simplification of the multiple-step build typical of Type I sourdoughs.

In Type II sourdoughs, yeast growth is slowed or stopped due to higher fermentation temperatures. These doughs are more liquid and once fermented may be chilled and stored for up to a week. They are pumpable and used in continuous bread production systems 7.

Type III sourdough

Type III sourdoughs are Type II sourdoughs subjected to a drying process, usually either spray or drum drying, and are mainly used at an industrial level as flavoring agents. They are dominated by “drying-resistant [lactic acid bacteria] such as Pediococcus pentosaceus, Lactobacillus plantarum, and L. brevis.” The drying conditions, time and heat applied, may be varied in order to influence caramelization and produce desired characteristics in the baked product 7.

Is sourdough bread healthy ?

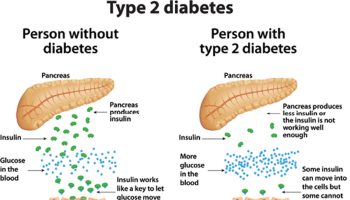

There is substantial interest in the role of dietary carbohydrate in preventing and managing type 2 diabetes 34. In North America, bread is the predominant carbohydrate-containing food, and consumption of white bread is 5 times that of whole wheat, rye, and other dark breads 35. Replacing white bread with whole-grain breads is often recommended to improve glycemic control 36. Epidemiologic studies have reported inverse associations between whole-grain consumption and the risk of type 2 diabetes and cardiovascular disease 37, 38, and clinical studies 39, 40 have reported beneficial effects of whole-grain consumption on the metabolic profile of subjects with impaired glycemic control. It has been suggested that the fiber content of whole-grain foods improves glucose/insulin metabolism by reducing the rate of carbohydrate breakdown and absorption 41, 42.

In an effort to identify a “healthier” bread, Mofidi and her colleagues 43 compare different breads effect on blood glucose, insulin response and insulin sensitivity in 12 obese or overweight men. The test breads were prepared to provide 50 g of available carbohydrate which required portions of 151 g for 11-grain (whole-grain, with sourdough culture), 157 g of sprouted-grain (whole-grain, with sourdough culture), 107 g of sourdough white, 122 g of 12-grain (whole-grain bread), and 110 g of white bread. Table 1 showed the five bread types used in her study and their nutrient compositions.

The test subjects (age: 53.9 ± 1.7 years) were overweight or obese males (body mass index (BMI): 25–35 kg/m2), nonsmokers and had no history of gastrointestinal disease, gluten allergy, dyslipidemia, or diabetes. Subjects did not take medications (with the exception of antidepressants and/or antihypertensives) or natural health products. Potential subjects were screened for glucose intolerance and diabetes at a prestudy visit using a standard 2 h oral glucose tolerance test (OGTT). Subjects were excluded if they had impaired fasting plasma glucose (>6.1 mmol/L), impaired glucose tolerance (>7.8 mmol/L at 2 h), or impaired fasting insulin (>90 pmol/L).

After collection of a fasting blood sample (time point −15 min), subjects consumed a serving of test bread with 250 mL of water within 15 min. Subsequently, blood samples were collected at 15, 30, 45, 60, 90, 120, 150, and 180 min.

Table 1. Nutrient composition of the test breads delivering 50 g available carbohydrate

| 11-grain | Sprouted-grain | Sourdough | 12-grain | White | |

|---|---|---|---|---|---|

| Total bread (g) | 151.0 | 157.2 | 107.3 | 122.2 | 110.3 |

| Available CHO (g) | 50.0 | 50.0 | 50.0 | 50.0 | 50.0 |

| Energy (kcal) | 320.2 | 336.4 | 277.9 | 317.8 | 273.7 |

| Starch (g) | 44.9 | 46.3 | 45.4 | 42.5 | 43.6 |

| Total sugars (g) | 5.1 | 3.6 | 4.5 | 7.4 | 6.4 |

| Soluble fiber (g) | 0.9 | 0.6 | 0.3 | 1.1 | 0.3 |

| Insoluble fiber (g) | 11.9 | 11.4 | 4.9 | 9.9 | 4.6 |

| Dietary fiber (g) | 12.8 | 12.1 | 5.2 | 11.0 | 4.9 |

| Protein (g) | 16.9 | 22.3 | 9.0 | 12.6 | 9.8 |

| Fat (g) | 3.1 | 2.9 | 4.3 | 5.2 | 3.6 |

What Mofidi et. al found was that the sprouted grain bread reduced the glycemic responses in both parts of the study and also that generally the whole-grain breads did not have what could be interpreted as beneficial, metabolic responses. When 50 g of available carbohydrate was ingested, the glucose response to sprouted-grain bread was significantly less than 11-grain, sourdough, and white breads. Additionally, the glucose response (overall and incremental) for 12-grain bread was significantly lower than sourdough and 11-grain breads. The favourable glucose responses to the sprouted-grain and 12-grain breads support their hypothesis that the sprouted-grain, whole-grain, and sourdough breads would lower the postprandial metabolic responses, in comparison to white bread. Greater fiber content in sprouted-grain and 12-grain breads (Table 1) may explain the lowered glycemia following their ingestion compared to white and sourdough breads 43. Dietary fiber is reported to attenuate glycemic response through its physical action in the gut which lowers the rate of carbohydrate digestion and absorption 44. In conclusion it is the fiber content in the bread that make them “healthier” bread, therefore it’s best to eat high fiber wholegrain, sprouted-grain or multigrain bread than refined white bread. or sourdough bread.

References- Sourdough. Wikipedia. https://en.wikipedia.org/wiki/Sourdough

- Davidson, Alan (1999). The Oxford Companion to Food. Oxford: Oxford University Press. pp. 756–757. ISBN 0192115790.

- Gaenzle, Michael (1 April 2014). “Sourdough Bread”. In Batt, Carl. Encyclopedia of Food Microbiology (2nd ed.). Academic Press. p. 309. ISBN 978-0123847300.

- Gobbetti, Marco; Gänzle, Michael (2012). Handbook on Sourdough Biotechnology. Springer. p. 6. ISBN 978-1-4614-5425-0.

- Scott, Alan; Daniel Wing (1999). The Bread Builders: Hearth Loaves and Masonry Ovens. White River Junction (VT): Chelsea Green Publishing Company. pp. 34–230. ISBN 1-890132-05-5.

- Peters, Erica J. San Francisco: A Food Biography. Rowman & Littlefield, 2013, p. 189.

- Weibiao Zhou; Nantawan Therdthai (2012). Y.H. Hui, E. Özgül Evranuz, eds. “Fermented Bread”. Handbook of Plant-Based Fermented Food and Beverage Technology (2 ed.). CRC Press: 477–526. ISBN 1439849048.

- United States Department of Agriculture Agricultural Research Service. USDA Branded Food Products Database. https://ndb.nal.usda.gov/ndb/search/list

- https://www.epicurious.com/archive/blogs/editor/2013/11/discovering-danish-rye-bread-rugbrod-smorrebrod.html

- http://www.sourdoughlibrary.org/homemade-traditional-pumpernickel/

- Robertson, Laurel; Flinders, Carol; Godfrey, Bronwen (2011). The Laurel’s Kitchen Bread Book: A Guide to Whole-Grain Breadmaking. Random House. pp. 111–131. ISBN 978-0-307-76116-3.

- http://azer.com/aiweb/categories/magazine/ai104_folder/104_articles/104_food_north_south.html

- http://www.exploratorium.edu/cooking/bread/recipe-injera.html

- http://www.shebayemenifood.com/content/lahoh-sanaani

- Steinkraus, Keith (1995). Handbook of Indigenous Fermented Foods, Second Edition. CRC Press. p. 149. ISBN 978-0-8247-9352-4.

- Golden, David M.; Jay, James M.; Martin J. Loessner (2005). Modern food microbiology. Berlin: Springer. p. 179. ISBN 0-387-23180-3.

- Weibiao Zhou; Nantawan Therdthai (2012). Y.H. Hui, E. Özgül Evranuz, eds. “Fermented Bread”. Handbook of Plant-Based Fermented Food and Beverage Technology (2 ed.). CRC Press: 477–526. ISBN 1439849048.

- Impact of sourdough on the texture of bread. Food Microbiol. 2007 Apr;24(2):165-74. Epub 2006 Sep 20. https://www.ncbi.nlm.nih.gov/pubmed/17008161

- Gänzle MG, Ehmann M, Hammes WP. Modeling of Growth of Lactobacillus sanfranciscensis and Candida milleri in Response to Process Parameters of Sourdough Fermentation. Applied and Environmental Microbiology. 1998;64(7):2616-2623. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC106434/

- Yiu H. Hui (2006). Handbook of food science, technology, and engineering. Washington, DC: Taylor & Francis. pp. 183–9–183–11. ISBN 0-8493-9849-5. Retrieved Dec 20, 2011.

- Gotthard Kunze; Satyanarayana, T. (2009). Yeast Biotechnology: Diversity and Applications. Berlin: Springer. p. 180. ISBN 1-4020-8291-6.

- Neubauer H, Glaasker E, Hammes WP, Poolman B, Konings WN. Mechanism of maltose uptake and glucose excretion in Lactobacillus sanfrancisco. Journal of Bacteriology. 1994;176(10):3007-3012. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC205458/

- Daeschel, M.A.; Andersson, R.E.; Fleming, H.P. (1987). “Microbial ecology of fermenting plant materials” https://fbns.ncsu.edu//USDAARS/Acrobatpubs/P190-220/p199.pdf

- Hammes, W.P.; Vogel, R.F. (1995). Holzapfel, W. H.; Wood, Brian J. B., eds. The Genera of lactic acid bacteria. London: Blackie Academic & Professional. pp. 19–35. ISBN 0-7514-0215-X.

- Gobbetti, M., A. Corsetti (1997). “Lactobacillus sanfrancisco a key sourdough lactic acid bacterium: a review” http://comenius.susqu.edu/biol/312/lactobacillussanfranciscoakeysourdoughlacticacidbacteriumareview.pdf

- Vogel, Rudi F. (1997). “Microbial ecology of cereal fermentations”. Food Technology and Biotechnology. 35 (1).

- C.J. Pollock; N.J. Chatterton (1980). “Fructans”. In P.K. Stumpf, E.E. Conn, J. Preiss. The Biochemistry of plants: a comprehensive treatise: Carbohydrates. 14. San Diego, California: Academic Press Inc. pp. 109–140. ISBN 0-12-675414-4.

- Lorenz, Klaus J.; Kulp, Karel (2003). Handbook of dough fermentations. New York: Marcel Dekker, Inc. pp. 23–50. ISBN 0-8247-4264-8.

- Van der Meulen R, Scheirlinck I, Van Schoor A, et al. Population Dynamics and Metabolite Target Analysis of Lactic Acid Bacteria during Laboratory Fermentations of Wheat and Spelt Sourdoughs . Applied and Environmental Microbiology. 2007;73(15):4741-4750. doi:10.1128/AEM.00315-07. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1951026/

- Yiu H. Hui (2006). Handbook of food science, technology, and engineering. Washington, DC: Taylor & Francis. pp. 183–9–183–11. ISBN 0-8493-9849-5.

- Nanna A. Cross; Corke, Harold; Ingrid De Leyn; Nip, Wai-Kit (2006). Bakery products: science and technology. Oxford: Blackwell. p. 370. ISBN 0-8138-0187-7.

- Golden, David M.; Jay, James M.; Martin J. Loessner (2005). Modern food microbiology. Berlin: Springer. p. 179. ISBN 0-387-23180-3.

- Sadeghi, A. (2008). “The Secrets of Sourdough; A Review of Miraculous Potentials of Sourdough in Bread Shelf Life”. Biotechnology(Faisalabad). 7 (3): 413–417. doi:10.3923/biotech.2008.413.417.

- Postprandial blood glucose as a risk factor for cardiovascular disease in Type II diabetes: the epidemiological evidence. Bonora E, Muggeo M. Diabetologia. 2001 Dec; 44(12):2107-14. https://www.ncbi.nlm.nih.gov/pubmed/11793012/

- The effect of particle size of whole-grain flour on plasma glucose, insulin, glucagon and thyroid-stimulating hormone in humans. Behall KM, Scholfield DJ, Hallfrisch J. J Am Coll Nutr. 1999 Dec; 18(6):591-7. https://www.ncbi.nlm.nih.gov/pubmed/10613410/

- Nutrition recommendations and interventions for diabetes–2006: a position statement of the American Diabetes Association. Bantle JP, Wylie-Rosett J, Albright AL, Apovian CM, Clark NG, Franz MJ, Hoogwerf BJ, Lichtenstein AH, Mayer-Davis E, Mooradian AD, Wheeler ML. Diabetes Care. 2006 Sep; 29(9):2140-57. http://care.diabetesjournals.org/content/29/9/2140.long

- Esmaillzadeh A, Mirmiran P, Azizi F. Whole-grain consumption and the metabolic syndrome: a favorable association in Tehranian adults. European Journal of Clinical Nutrition. 2005;59(3):353–362. https://www.ncbi.nlm.nih.gov/pubmed/15536473

- Newby P, Maras J, Bakun P, Muller D, Ferrucci L, Tucker KL. Intake of whole grains, refined grains, and cereal fiber measured with 7-d diet records and associations with risk factors for chronic disease. The American journal of clinical nutrition. 2007;86(6):1745-1753. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2646086/

- Pereira MA, Jacobs DR, Jr., Pins JJ, et al. Effect of whole grains on insulin sensitivity in overweight hyperinsulinemic adults. American Journal of Clinical Nutrition. 2002;75(5):848–855. http://ajcn.nutrition.org/content/75/5/848.long

- Rave K, Roggen K, Dellweg S, Heise T, Tom Dieck H. Improvement of insulin resistance after diet with a whole-grain based dietary product: results of a randomized, controlled cross-over study in obese subjects with elevated fasting blood glucose. British Journal of Nutrition. 2007;98(5):929–936. https://www.ncbi.nlm.nih.gov/pubmed/17562226

- Nilsson AC, Ostman EM, Holst JJ, Bjorck IME. Including indigestible carbohydrates in the evening meal of healthy subjects improves glucose tolerance, lowers inflammatory markers, and increases satiety after a subsequent standardized breakfast. Journal of Nutrition. 2008;138(4):732–739. http://jn.nutrition.org/content/138/4/732.long

- Weickert MO, Mohlig M, Schofl C, et al. Cereal fiber improves whole-body insulin sensitivity in overweight and obese women. Diabetes Care. 2006;29(4):775–780. http://care.diabetesjournals.org/content/29/4/775.long

- Mofidi A, Ferraro ZM, Stewart KA, et al. The Acute Impact of Ingestion of Sourdough and Whole-Grain Breads on Blood Glucose, Insulin, and Incretins in Overweight and Obese Men. Journal of Nutrition and Metabolism. 2012;2012:184710. doi:10.1155/2012/184710. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3317179/

- Fiber and starchy foods: gut function and implications in disease. Jenkins DJ, Jenkins AL, Wolever TM, Rao AV, Thompson LU. Am J Gastroenterol. 1986 Oct; 81(10):920-30. https://www.ncbi.nlm.nih.gov/pubmed/3020970/