What is kefir

Kefir is an acidic-alcoholic fermented milk beverage with little acidic taste and creamy consistency produced by the action of bacteria and yeasts that exist in symbiotic association in kefir grains 1. The beverage is self-carbonated that owes its distinctive flavor to a mixture of lactic acid, ethanol, carbon dioxide and other flavor products, such as acetaldehyde 2. The unique flavor is the result of the symbiotic metabolic activity of a number of lactic bacteria and yeast species 3. The typical yoghurt flavor kefir is caused by lactic bacteria that produce lactic acid, which imparts an acidic and refreshing taste, and the mixture of various carbonyl compounds like acetone, diacetyl, and acetaldehyde of which the latter is considered the major flavour component 4. The word kefir is derived from the Turkish word keyif, which means “feeling good” after its ingestion 5. The main products of kefir fermentation are lactic acid, ethanol and CO2 (carbon dioxide), which confer this beverage viscosity, acidity and low alcohol content. Minor components can also be found, including diacetyl, acetaldehyde, ethyl and amino acids contributing to the flavour composition 6. This drink differs from other fermented dairy products because it is not the result of the metabolic activity of a single or a few microbial species 7.

The milk fermentation is achieved by the of kefir grains, a cluster of microorganisms held together by a polysaccharide matrix named kefiran 8. Kefir grains are an example of symbiosis between yeast and bacteria 8. Kefir grains have been used over years to produce kefir, a fermented beverage that is consumed all over the world, although its origin is in the Caucasus Mountains, a traditional product highly consumed in Eastern Europe, Russia and Southwest Asia 5. A vast variety of different species of organisms forming the kefir grains, comprising yeast and bacteria, have been isolated and identified. Kefir is a probiotic food. Probiotics have shown to be beneficial to health, being presently of great interest to the food industry. Kefir has been accredited with antibacterial, antifungal and antitumoural activities among other beneficial attributes.

Kefir grains are added to different types of milk. It can be made from any type of milk; cow, goat or sheep, coconut, rice and soy but commonly cow milk is used. The grains cause its fermentation that results in the production of numerous components in the kefir, including lactic acid, acetic acid, CO2, alcohol (ethyl 2 alcohol) and aromatic compounds. That provides kefir’s unique sensory characteristics: fizzy, acid taste, tart and refreshing flavor 9. The beverage contains vitamins, minerals and essential amino acids that help the body with healing and maintenance functions and also contains easily digestible complete proteins 3. The benefits of consuming kefir in the diet are numerous 10: antitumor activity 11, antimicrobial activity 12, antiinflammatory, and antiallergic activity 13.

Currently, an increase in kefir consumption in many countries has been reported, due to its unique sensory properties and long history associated with beneficial effects on human health 14. In Brazil, the knowledge of this beverage, as well as the benefits of the inclusion of probiotic food in a regular diet, are not very widespread, and kefir manufacturing is exclusively artisanal 15.

Kefir Grains

Kefir grains are small irregularly shaped, yellowish-white, hard granules which resemble miniature cauliflower blossoms see Figure 1 16. Kefir grains vary in size, from 0.3 to 3.0 cm in diameter (Figure 1), are characterized by an irregular, multi-lobular surface, united by a single central section, and their color varies from white to yellowish white. The grains are elastic and have a viscous and firm texture 17.

Kefir grains have a complex composition of microbial species such as the predominance of lactic acid bacteria, acetic bacteria, yeasts, and fungi 18, 19. This microbial species are classified into four groups 20:

- homofermentative and heterofermentative lactic acid bacteria

- and lactose and non-lactose assimilating yeast.

In kefir, lactic acid bacteria are primarily responsible for the conversion of the lactose present in milk into lactic acid, which results in a pH decrease and milk preservation. Other kefir microbial constituents include lactose-fermenting yeasts that produce ethanol and CO2. Non-lactose fermenting yeast and acetic acid bacteria also participate in the process 17. After fermentation the grains increase in about 5–7% of their biomass. During their growth in milk, the microorganism proportions in the grains differ from those present in the final product 6. This difference is associated with the fermentation process conditions such as fermentation time, temperature, degree of agitation, type of milk, grain/milk inoculum ratio and microorganism distribution, among others 6.

In that way, lactic acid bacteria, Lactobacillus paracasei ssp. paracasei, Lactobacillus acidophilus, Lactobacillus delbrueckii ssp. bulgaricus, Lactobacillus plantarum, and L. kefiranofaciens are predominant species. However, these species represent only 20% of the Lactobacillus in the final fermented beverage, with the remainder consisting of 80% Lactobacillus kefiri 21. Acetobacter aceti and Acetobacter rasens have also been isolated, such as the fungus Geotrichum candidum. More than 23 different yeast species have been isolated from kefir grains and from fermented beverages of different origins. However, the predominant species are Saccharomyces cerevisiae, Saccharomyces unisporus, Candida kefyr, and Kluyveromyces marxianus ssp. marxianus 22 see Table 1.

Figure 1. Macroscopic structure of kefir grains

Kefir grains play a natural starter culture role during the production of kefir and are recovered after the fermentation process by milk straining 6. These grains are composed of microorganisms immobilized on a polysaccharide and protein matrix, where several species of bacteria and yeast coexist in symbiotic association 23.

In kefir grains the main polysaccharide is kefiran, which is a heteropolysaccharide composed by equal proportions of glucose and galactose and is mainly produced by Lactobacillus kefiranofaciens 24. It has been demonstrated that kefiran improves the viscosity and viscoelastic properties of acid milk gels 25, and is able to form gels that have interesting viscoelastic properties at low temperatures, because of that, kefiran can also be used as an additive in fermented products. Besides, kefiran can enhance the rheological properties of chemically acidified skim milk gels increasing their apparent viscosity 26.

Compared with other polysaccharides, kefiran has outstanding advantages such as antitumor, antifungal, antibacterial properties 27, immunomodulation or epithelium protection 28, anti-inflammatory 29, healing 12, and antioxidant activity 30.

Table 1. Microbial compositions found in kefir and kefir grains of different origins

| Microorganism | Source – Country |

|---|---|

| Lactobacillus kefir, Lactobacillus kefiranofaciens, Lactobacillus paracasei, Lactobacillus plantarum, Lactococcus lactis ssp. lactis, Kluyveromyces marxianus, Lactobacillus parakefir, Saccharomyces cerevisiae, Saccharomyces unisporus, Leuconostoc mesenteroides, Acetobacter sp., Saccharomyces sp., Lactococcus lactis ssp. lactis biovar diacetylactis, Lactococcus lactis, Lactobacillus kefiri, Lactobacillus parakefiri | Kefir grains and beverage – Argentina |

| Lactobacillus kefiri, Lactobacillus kefiranofaciens, Leuconostoc mesenteroides, Lactococcus lactis, Lactococcus lactis ssp. cremoris, Gluconobacter frateurii, Acetobacter orientalis, Acetobacter lovaniensis, Kluyveromyces marxianus, Naumovozyma sp., Kazachastania khefir | Kefir grains and beverage – Belgium |

| Lactobacillus kefiri, Lactobacillus kefiranofaciens, Leuconostoc mesenteroides, Lactococcus lactis, Lactobacillus paracasei, Lactobacillus helveticus, Gluconobacter japonicus, Lactobacillus uvarum, Acetobacter syzygii, Lactobacillus satsumensis, Saccharomyces cerevisiae., Leuconostoc sp., Streptococcus sp., Acetobacter sp., Bifidobacterium sp., Halococcus sp., Lactobacillus amylovorus, Lactobacillus buchneri, Lactobacillus crispatus, Lactobacillus kefiranofaciens ssp. kefiranofaciens, Lactobacillus kefiranofaciens ssp. kefirgranum, Lactobacillus parakefiri | Kefir grains – Brazil |

| Lactobacillus brevis, Lactobacillus delbrueckii ssp. bulgaricus, Lactobacillus helveticus, Streptococcus thermophilus, Lactobacillus casei ssp. pseudoplantarum, Kluyveromyces marxianus var. lactis, Saccharomyces cerevisiae, Candida inconspicua, Candida maris, Lactobacillus lactis ssp. lactis | Kefir grains and beverage – Bulgaria |

| Lactobacillus paracasei, Lactobacillus parabuchneri, Lactobacillus casei, Lactobacillus kefiri, Lactococcus lactis, Acetobacter lovaniensis, Kluyveromyces lactis, Kazachstania aerobia, Saccharomyces cerevisiae, Lachancea meyersii | Kefir beverage – Brazil |

| Lactobacillus kefiranofaciens, Leuconostoc mesenteroides, Lactococcus lactis, Lactobacillus helveticus, Kluyveromyces marxianus, Saccharomyces cerevisiae, Pseudomonas sp., Kazachstania unispora, Kazachstania exigua, Lactobacillus kefiri, Lactobacillus casei, Bacillus subtilis, Pichia kudriavzevii, Leuconostoc lactis, Lactobacillus plantarum, Acetobacter fabarum, Pichia guilliermondii, Lactococcus sp., Lactobacillus sp., Acetobacter sp., Shewanella sp., Leuconostoc sp., Streptococcus sp, Acinetobacter sp., Pelomonas sp., Dysgonomonas sp., Weissella sp., Shewanella sp. | Kefir grains (Tibet)– China |

| Acetobacter acetic, Enterococcus faecalis, Enterococcus durans, Lactococcus lactis ssp. cremoris, Leuconostoc pseudomesenteroides, Leuconostoc paramesenteroides, Lactobacillus brevis, Lactobacillus acidophilus, Saccharomyces sp., Brettanomyces sp., Candida sp., Saccharomycodes sp., Acetobacter rancens | Kefir beverage – China |

| Lactobacillaceae and Streptococcaceae | Kefir grains and beverage – Ireland |

| Lactobacillus kefiranofaciens, Dekkera anomala, Streptococcus thermophilus, Lactococcus lactis, Acetobacter sp., Lactobacillus lactis, Enterococcus sp., Bacillus sp., Acetobacter fabarum, Acetobacter lovaniensis, Acetobacter orientalis | Kefir grains – Italy |

| Leuconostoc sp., Lactococcus sp., Lactobacillus sp., Lactobacillus plantarum, Zygosaccharomyces sp., Candida sp., Candida lambica, Candida krusei, Saccharomyces sp., Cryptococcus sp. | Kefir grains and beverage – South Africa |

| Lactobacillus sp., Leuconostoc sp., Lactococcus sp., Zygosaccharomyces sp., Candida sp., Saccharomyces sp. | Kefir grains – South Africa |

| Lactobacillus kefiri, Lactobacillus kefiranofaciens, Leuconostoc mesenteroides, Lactococcus lactis, Escherichia coli, Pseudomonas sp., Saccharomyces turicensis, | Kefir grains – Taiwan |

| Lactobacillus kefiri, Leuconostoc mesenteroides, Lactococcus lactis, Streptococcus thermophilus, Lactobacillus kefiranofaciens, Lactobacillus acidophilus | Kefir grains and beverage – Turkey |

| Lactobacillus helveticus, Lactobacillus buchneri, Lactobacillus kefiranofaciens, Lactobacillus acidophilus, Lactobacillus helveticus, Streptococcus thermophilus, Bifidobacterium bifidum, Kluyveromyces marxianus | Kefir grains – Turkey |

| Lactococcus cremoris, Lactococcus lactis, Streptococcus thermophilus, Streptococcus durans | Kefir beverage – Turkey |

The microbial composition may vary according to kefir origin, the substrate used in the fermentation process and the culture maintenance methods. Tibetan kefir, which is used in China, is composed of Lactobacillus, Lactococcus, and yeast. Additionally, acetic acid bacteria have been identified in Tibetan kefir, depending on the region in China from where it was obtained 32, additionally, Tibetan kefir composition differs from that of Russian kefir, Irish kefir, Taiwan kefir, Turkey fermented beverage with kefir; however, it is known that this microbial diversity is responsible for the physicochemical features and biological activities of each kefir 33. The complex interactions between yeast and bacteria and their interdependence in kefir grains are not completely understood. However, when the bacteria are separated from the grain, yeast will not grow as efficiently 6.

Due to its high capacity to metabolize lactose 34, the genus Lactococcus tends to grow faster than yeast in milk 5. This genus hydrolyzes lactose, producing lactic acid and a suitable environment for yeast growth 5. Moreover, yeasts synthesize complex B vitamins and hydrolyze milk proteins, using oxygen to produce CO2 and ethanol 35. The interaction between yeast and lactic acid bacteria can be stimulated or inhibited by the growth of one or both, in co-cultures. These microorganisms can compete for nutrients for growth, or may produce metabolites that inhibit or stimulate one another 35. Some yeast species are proteolytic or lipolytic, providing amino acids and fatty acids 6. Species such as Debaryomyces hansenii and Yarrowia lipolytica assimilate the lactic acid formed by lactic acid bacteria, raising the pH and stimulating bacteria growth. The production of vitamin B by Acetobacter spp. also favors the growth of other microorganisms present in kefir grains 35.

Wang et al. 36 examined a section of a whole kefir grain and found in the outer layer of the grain, lactococci, and yeasts, and, in the inner layer of the grain, the quantity of lactobacilli were much higher and more yeasts cells were found. There are little information about the mechanism of grain formation, so the same authors, proposed a hypothesis to explain that. “Initially, Lactobacillus kefiranofaciens and Saccharomyces turicensis start to auto-aggregate and co-aggregated to small granules.” The aggregation is enhanced when the pH drops. The biofilm producers, Lactobacillus kefiri, Kluyveromyces marxianus HY1, and Pichia fermentans HY3 then adhere to the surface of these small granules due to their cell surface properties and their strong aggregation ability, which gives rise to thin biofilms. After biofilm formation, the kefir yeasts and Lactobacillus continue to co-aggregated with the granule strains and associate with the granule biofilm to become a three dimensional microcolony. As the cell density due to the growth of kefir yeasts and Lactobacillus increases, cells and milk components that are present in the liquid phase accumulate on the granule surface and the kefir grains are formed. There is a symbiotic relation between the microorganisms present in kefir grains, wherein the bacteria and yeast survive and share their bioproducts as power sources and microbial growth factors. This microorganism association is responsible for lactic and alcoholic fermentation 37. In this ecosystem there is a relatively stable microorganism population, which interacts with and influences other members of the community. This population provides the synthesis of bioactive metabolites, which are essential for grain growth and microorganism inhibition, such as food pathogens and contaminants 23.

Kefir production

There are three main ways of producing kefir (I) the artisanal “traditional” process, (II) the commercial process by the Russian method and (III) the commercial process using pure cultures 6. Other substrates may also be used, such as milk from other animal species, coconut milk, soybean milk, fruit juices and/or sugar and molasses solutions 38.

The traditional artisanal production involves milk inoculation with a variable amount of kefir grains and fermentation for a period between 18–24 hour at 20–25 °C. At the end of the fermentation process the grains are sieved and can be used for a new fermentation or kept (1–7 days) in fresh milk, while the kefir beverage is stored at 4 °C, ready for consumption 7.

The initial inoculum concentration of the grains (grain/milk proportion) affects the pH, viscosity, final lactose concentration and the microbiological profile of the final product 39. Agitation during fermentation also influences kefir microbial composition, favoring the development of homofermentative lactococci and yeast 6. Incubation at temperatures above 30 °C stimulates the growth of thermophilic lactic acid bacteria, while being a disadvantage for yeast growth and mesophilic lactic acid bacteria 6.

The second method, known as the “Russian method”, allows for the production of kefir on a larger scale, and uses a process of fermentation in series, from the percolate resulting from the first fermentation of the grains (fermented without the grains or mother culture) 6.

Different methods can be used in the industrial process of kefir production, but all based on the same principle. The milk is inoculated with pure cultures isolated from kefir grains and commercial cultures 6. The maturation phase can be performed or not, consisting of maintaining the kefir at 8–10 °C for up to 24 h 6, to allow microorganism, primarily yeast, growth, contributing to the specific flavor of the product 40. Omission of this step is associated with development of atypical flavor in kefir 40.

During storage, the CO2 production by yeast or heterofermentative lactic acid bacteria can cause bloating in the product package, a fact that should be considered in the choice of packaging 7.

Although the commercial beverage is available in many countries, not all the properties of traditional kefir are always present 7. Assadi et al. 41 tested several ratios of starter cultures isolated from the grains (lactic acid bacteria, yeast, acetic acid bacteria), and found that traditional kefir produced with kefir grains has been better accepted than kefir obtained by using the starter culture. Rossi and Gobbetti 42 produced a “kefir-type” beverage, with lower viscosity and the absence of some of the volatile components often found in traditional kefir. Carneiro 43 on the other hand, developed a starter culture from microorganisms isolated from Kefir grains and the product was more accepted that the traditional kefir. Beshkova et al. 40 proposed two methods of kefir fermentation: one by simultaneous fermentation and one by successive fermentation. Therefore, they used a starter culture consisting of bacteria and yeast isolated from kefir grains, combined to two strains commonly used in yogurt manufacturing. Yeasts were added to the starter culture with sucrose, both at the beginning (simultaneous fermentation) and after the lactic acid fermentation step (successive fermentation). The two fermentation processes produced kefir with high number of viable lactococci and lactobacilli, with sensory properties similar to traditional kefir.

The use of commercial cultures can standardize the commercial production of kefir, if the selection of species and strains of yeasts and bacteria is carried out accurately and carefully, thus allowing for the production of a “kefir-type” beverage with acceptable flavor and good conservation properties 43. The commercial beverage may have a commercial life period of up to 28 days, while it is recommended that kefir produced with grains be consumed between 3–12 days. However, the “kefir-type” beverage may not present the same therapeutic and probiotic properties present in traditional kefir 6.

The development of a “kefir-type” beverage is not the only industrial application that has been investigated. Kefir grains have also been studied regarding the production of single cell protein in the bioconversion of cheese whey and their application in the food industry, to improve the sensory characteristics of certain products 44.

The main deficiencies in kefir manufacturing can be attributed to unpleasant taste and aroma typical of yeast 5. The latter can be caused by rapid growth of S. cerevisiae, accompanied by a typical vinegar aroma 5. The excessive production of acetic acid can also influence kefir aroma, and occurs due to the intense growth of Acetobacter spp. or the presence of Dekkera spp. in the grains. A bitter taste may be caused by fungi (for example Geotrichum candidum) and/or the activity of some atypical yeasts which may be present in the product 5.

Biological Activity of Kefir

Due to its composition, kefir is mainly considered a probiotic resource 45. “Probiotics are microbial cell preparations or components of microbial cells with a beneficial effect on the health of the host” 46. Some studies suggest that probiotic bacteria in kefir consumers’ gut are abundant and are correlated with health improvement 47, 48; in that way, it had been demonstrated that the cell-free fraction of kefir enhances the ability to digest lactose relieving symptoms 49.

Another reason for the increased interest in probiotic strains from kefir is its capacity to lower cholesterol levels. There are different ways in which bacteria can alter serum cholesterol 50:

- (i) through the binding to and absorption into the cell before it can be absorbed into the body;

- (ii) producing free and deconjugating bile acids;

- (iii) inhibiting the enzyme HMG-CoA reductase.

The microorganisms in the kefir grains produce lactic acid, antibiotics and bactericides, which inhibit the development of degrading and pathogenic microorganisms in kefir milk 51. Kefir acts against the pathogenic bacteria Salmonella, Helicobacter, Shigella, Staphylococcus, Escherichia coli, Enterobacter aerogenes, Proteus vulgaris, Bacillus subtilis, Micrococcus luteus, Listeria monocytogenes, Streptococcus pyrogenes 35, Streptococcus faecalis KR6, Fusarium graminearum CZ1 52, and the fungus Candida albicans. On the other hand, it has been demonstrated that a mixture of kefir isolated bacteria and yeast is able to prevent diarrhea and enterocolitis triggered by Clostridium difficile 53. Besides, kefir showed good efficacy in inhibiting spore formation and aflatoxin B1 produced by the fungus Aspergillus flavus, which is a toxic compound formed either in the field or during food storage. Therefore, kefir appears as a promising safe alternative natural food preservative offering protection against intoxication with aflatoxin B1 52.

It had been proved that many species of lactobacilli present in kefir have S-layer proteins. Surface layers (S-layers) can be aligned in unit cells on the outermost surface of many prokaryotic microorganisms 54. It has been demonstrated that these S-layer proteins can apply a protective action inhibiting the grown of Salmonella enterica serovar Enteritidis in Caco-2 cells, and also have the ability to antagonize the effects of toxins from Clostridium difficile on eukaryotic/eukaryotic cells in vitro 55.

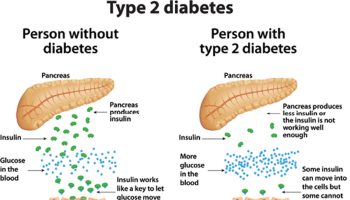

However, there are other important bioactivities that have been tested with kefir grains, the cell-free fraction of kefir or acid lactic bacteria isolated from kefir, such as antitumoral 56, anti-inflammatory 57, antimicrobial (Anselmo R. J., Viora S. S., Ojeda P. A., Lausada L. I. (2010). Efecto antagónico del kefir sobre endosporas y células vegetativas de Bacillus cereus y Clostridium perfringens. (Spanish) Antagonistic effect of the kefir on endospores and vegetative cells of Bacillus cereus and Clostridium perfringens. Inf. Tecnol. 21 131–138.)), immunoregulatory 58, antiallergenic 59, wound healing 60, antidiabetic 61, antimutagenic 62, and antigenotoxic 63. In that way, it had been demonstrated that kefir cell-free fraction has antiproliferative effects on human gastric cancer SGC7901 cells 56, colon adenocarcinoma cells 64, HuT–102 malignant T lymphocytes, sarcoma 180 in mice, Lewis lung carcinoma and human mammary cancer 49, and reduce oxidative stress 65. Another study has shown that suspensions after 24 h fermentation and mechanically disintegrated kefir grains cause a significant inhibition of granuloma tissue formation and a 43% inhibition of the inflammatory process 57.

In addition, there are other important studies performed with some microorganisms isolated from different types of kefir. Some microorganisms with their biological activities and origin are shown in Table 2.

Table 2. Kefir microorganisms and their biological activities

| Organism of interest | Origin | Biological activity |

|---|---|---|

| Lactobacillus plantarum MA2 | Tibetan kefir | Hypocholesterolemic effect |

| Lactobacillus plantarum Lp27 | Tibetan kefir | Inhibited cholesterol absorption |

| Lactobacillus plantarum CIDCA 83114 | Kefir grains – Argentina | Inhibit the growth of Shigella sonnei in vitro and also the cytotoxicity of C. difficile toxins on eukaryotic cells |

| Lactobacillus kefir CIDCA 8348 | Kefir grains – Argentina | Inhibit the growth of Shigella sonnei in vitro and also the cytotoxicity of C. difficile toxins on eukaryotic cells |

| Lactobacillus plantarum ST8KF | Kefir grains – South Africa | Bactericida effect against: Lactobacillus casei, Lactobacillus salivarius, Lactobacillus curvatus, Listeria innocua |

| Lactobacillus kefiranofaciens K1 | Kefir grains – Taiwanese milk | Antiallergenic effect |

| Lactobacillus kefiranofaciens M1 | Kefir grains – Taiwanese milk | Immunoregulatory effects – anticolitis effect |

| Lactobacillus lactis CIDCA 8221 | Kefir grains – Argentina | Inhibit the growth of Shigella sonnei in vitro and also the cytotoxicity of Clostridium difficile toxins on eukaryotic cells |

| Kluyveromyces marxianus CIDCA 8154 | Kefir grains – Argentina | Inhibit the growth of Shigella sonnei in vitro and also the cytotoxicity of Clostridium difficile toxins on eukaryotic cells |

| Saccharomyces cerevisiae CIDCA 8112 | Kefir grains – Argentina | Inhibit the growth of Shigella sonnei in vitro and also the cytotoxicity of Clostridium difficile toxins on eukaryotic cells |

| Lactobacillus lactis ssp. cremoris | Kefir grains – India | Activity against food spoilage bacteria |

Kefiran, A Potential Exopolysaccharide

The increased search for natural polysaccharides has been very significant due to their use in the food, pharmaceutical, and cosmetic industries as additives, bio-absorbents, metal removal agents, bioflocculants, and medicine delivery agents, among other functions 66. Many microorganisms, such as bacteria, fungi, and weeds, have the capacity/ability to synthesize and excrete extracellular polysaccharides, and these polysaccharides can be either soluble or insoluble 67.

The polysaccharides that are commonly used as food additives are xanthan, dextran, gellan, and alginates, while the exopolysaccharides produced by lactic acid bacteria show good physicochemical characteristics for their use as food additives. In addition to these characteristics, exopolysaccharides are obtained from microorganisms classified as GRAS (generally recognized as safe), such as lactic acid bacteria 68.

Many reports have demonstrated that the quantity and properties of exopolysaccharides depend on the microorganisms used in the fermentation process and on the fermentation conditions and the composition of the culture media 69. Exopolysaccharides have physicochemical and rheological properties that make them suitable as additives, which can be used as stabilizers, emulsifiers, gelling agents, and viscosity improvers. Additionally, exopolysaccharides possess biological properties suggesting their use as antioxidants, antitumor agents, antimicrobial agents, and immunomodulators, among other roles 70.

The exopolysaccharides kefiran is produced by Lactobacillus kefiranofaciens 71 from kefir grains, which are composed of proteins, polysaccharides, and a complex symbiotic microbial mixture 72. These microorganisms grow in kefiran, which is a polysaccharide matrix consisting of glucose and galactose. Despite good kefiran production by L. kefiranofaciens alone, it has been observed that the addition of Saccharomyces sp. to the culture improves the net quantity of kefiran, illustrating the importance of the symbiosis between the bacteria and yeast that are present in kefir 73.

Lactic acid bacteria can synthesize homopolysaccharides or heteropolysaccharides. The synthesized homopolysaccharides are glucans or fructans, which are composed of only one type of monosaccharide, glucose or fructose, respectively 74, whereas the heteropolysaccharides contain different types of monosaccharides in different proportions (mainly glucose, galactose, and rhamnose) 75.

Similarly to lactic acid bacteria, Lactobacillus sp. also produces glucan and fructan. The homopolysaccharides show a much higher performance compared with heteropolysaccharide production 76.

The heteropolysaccharides excreted by Lactobacillus delbrueckii, Lactobacillus bulgaricus, Lactobacillus rhamnosus, and Lactobacillus helveticus contain galactose, glucose, and rhamnose as the main monosaccharides, with other monosaccharides being present in smaller concentrations. They are also highly branched with different types of linkages, and their denominations are complex and generally dependent on the main monosaccharide 77.

Lactobacillus plantarum isolated from Tibetan kefir excretes exopolysaccharides classified as heteropolysaccharides composed of galactose, glucose, and mannose. This exopolysaccharides has the capacity/ability to reduce blood cholesterol and form a biofilm shape 78, 67.

Kefiran is an exopolysaccharides classified as a heteropolysaccharide comprising glucose and galactose in high concentrations, and it is classified as a water-soluble glucogalactan, which makes it suitable to be used as an additive 67. Kefiran has excellent rheological properties and can significantly improve the viscosity of lacteous products by favoring and maintaining gel properties and avoiding the loss of water during storage 25. With respect to the biological activity of kefiran, several studies have demonstrated that this exopolysaccharides can be used as a nutraceutical, as described in Table 3.

Table 3. Biological activity of kefiran

| Exopolysaccharide | Biological activity |

|---|---|

| Kefiran | Reduction of blood pressure induced by hypertension |

| Favors the activity of peritoneal macrophages | |

| Increase in peritoneal IgA | |

| Antitumoral activity | |

| Antimicrobial activity | |

| Modulation of the intestinal immune system and protection of epithelial cells against Bacillus cereus exocellular factors |

Kefir-Based Products

Nowadays, the interest in developing functional foods is increasing because people want to improve their health and prevent diseases. Keeping in mind that kefir is a beverage with high probiotic activity, among other bioactivities, new companies are emerging around the world. One of the biggest kefir companies known is Lifeway, which started in 1986; their products can be obtained in the United States, Canada, and Great Britain, all of them based in kefir beverages, frozen, and cheese.

Other companies are Evolve Kefir with its principal product, a smoothie; Wallaby Yogurt Company with Low Fat Kefir; and CocoKefir LLC, which provides drinks/beverages based mainly on coconut water cultured with a comprehensive blend of probiotics. Table 4 summarizes the products provided these companies with some general information about each one.

Table 4. Marketed kefir-based products and their information

| Companies | Product | General information |

|---|---|---|

| Lifeway • United States • Canada • Great Britain | Low Fat Kefir Non-Fat Kefir Veggie Kefir | All-natural 99% lactose-free Gluten-free 12 probiotic cultures High in protein and calcium |

| Kefir Oats | All-natural 99% lactose-free Gluten-free 12 probiotic cultures Oat fiber enriched High in protein and calcium | |

| Perfect 12 Kefir Traditional Kefir Greek Style Kefir | All-natural 99% lactose-free Gluten-free 12 probiotic cultures No added sugar High in protein and calcium | |

| Low Fat Kefir (Organic) | USDA Certified Organic Oregon Tilth Certified Organic 99% lactose-free Gluten-free 12 probiotic cultures High in protein and calcium | |

| Whole Milk Kefir (Organic) | USDA Certified Organic Oregon Tilth Certified Organic 99% lactose-free Gluten-free 12 probiotic cultures No added sugar | |

| Helios Kefir (Organic) | USDA Certified Organic Oregon Tilth Certified Organic 99% lactose-free Gluten-free Seven probiotic cultures Contains Inulin | |

| Green Kefir (Organic) | USDA Certified Organic Oregon Tilth Certified Organic 99% lactose-free Gluten-free 12 probiotic cultures Phytoboost = 1 serving of vegetables | |

| ProBugs (organic) | USDA Certified Organic Oregon Tilth Certified Organic 99% lactose-free Gluten-free 12 probiotic cultures No-spill pouch | |

| ProBugs Blast (Organic) | USDA Certified Organic Oregon Tilth Certified Organic 99% lactose-free Gluten-free 12 probiotic cultures High in protein and calcium | |

| Frozen ProBugs (Organic) | All-natural 99% lactose-free Gluten-free 10 probiotic cultures High in protein and calcium | |

| Frozen Kefir | All-natural 99% lactose-free 10 probiotic cultures 90 calories per serving 1 g of fat | |

| Frozen Kefir Bars | All-natural 99% lactose-free Gluten-free 10 probiotic cultures 60 calories per serving 0.5 g of fat | |

| BioKefir | All-natural 20 Billion units of probiotics 12 probiotic cultures 99% lactose-free Gluten-free High in protein and calcium | |

| Farmer Cheese | 99% lactose-free Gluten-free High in protein and calcium | |

| Evolve Kefir • United States | Evolve Kefir | 11 probiotic cultures. Natural fruit flavors. Fiber. Protein and calcium |

| Wallaby Organic • Australia | Lowfat Kefir | 12 different strains of Live and Active Kefir cultures. |

| CocoKefir • United States | CocoKefir App le Cinnamon CocoKefir Citrus CocoKefir CocoYo Body Ecology Coconut Kefir | Dairy, gluten, soy, and fat free Low calorie Contains valuable nutrients such as potassium, manganese, and magnesium. Beneficial probiotic strains |

Kefir health benefits

Historically, kefir has been recommended for the treatment of several clinical conditions such as gastrointestinal problems, hypertension, allergies, and ischemic heart disease 6. However, the variability inherent in kefir production conditions in different assays makes it difficult to conduct comparisons between reported scientific results 6.

Kefir grain fermentations from various substrates have been evaluated 38 and a wide variety of bioactive compounds have been observed, such as organic acids, CO2, H2O2 (hydrogen peroxide), ethanol, bioactive peptides, exopolysaccharides (kefiran), and bacteriocins. These compounds may act independently or together to produce the various health benefits attributed to kefir consumption 23.

Benefits for the digestive tract

Probiotics are defined as food with viable microorganisms that exhibit a beneficial effect on the host’s health when they are ingested. The most popular probiotic microorganisms are bacteria but at the moment the usefulness of some yeast as probiotics is being studied. The effect caused by kefir consumption in the intestinal microbiota composition may be due to a combination of factors, such as direct pathogen inhibition by acids and bacteriocin production, besides competitive pathogen exclusion in the intestinal mucosa 6. According to Marquina et al. 79 kefir consumption significantly increased lactic acid bacteria counts in the intestinal mucosa and reduced enterobacteria and clostridia populations. Furthermore, kefir consumption also prevented C. jejuni colonization in chick ceca 80, and was effective in postoperative treatments and in patients with gastrointestinal disorders 81. In Russia, kefir has been used by researchers in the treatment of peptic ulcers in the stomach and duodenum of human patients 7.

Lactose Intolerance

The ability to decrease lactose concentrations and the presence of β-galactosidase activity in fermented milk products make them suitable for consumption by people classified as lactose intolerant 7. It has been demonstrated that some kefir grains show β-galactosidase enzyme activity, which stays active when consumed, and that kefir contains less lactose than milk 81. β-galactosidase, which is naturally present in kefir grains, reduces the lactose content through hydrolysis process thus making the product suitable for lactose intolerant persons 82. A commercial kefir 83 proved to be as effective as yoghurt in reducing expired hydrogen and flatulence in lactose intolerant adults when compared to the ingestion of milk. de Vrese et al. 84 demonstrated that pigs fed with kefir showed a significant increase in galactose plasma concentrations, suggesting improvement of intestinal lactose hydrolysis by the microbial enzyme β-galactosidase.

Hypocholesterolemic Effect

Possible mechanisms proposed for the hypocholesterolemic activity in lactic acid bacteria may involve the inhibition of the exogenous cholesterol absorption in the small intestine, by the binding and incorporation of cholesterol to bacterial cells and cholesterol uptake, as well as suppression of bile acid reabsorption by enzymatic deconjugation of bile salts, promoted by the bile salt hydrolase enzyme 50. Wang et al. 50 observed a significant reduction in serum levels of total cholesterol, low density lipoproteins (LDL “bad” cholesterol) and triglycerides, while there was no change in high density lipoprotein (HDL-“good” cholesterol) levels in mice fed cholesterol-rich a diet supplemented with Lactobacillus plantarum MA2. Moreover, total cholesterol and triglycerides in the liver were also reduced. Cholesterol and triglycerides in animal feces, on the other hand, increased significantly. Another study 85 also observed a reduction of serum triglyceride and cholesterol levels, especially the non-HDL-C fraction. A contradictory result was reported by St-Onge et al. 86, where kefir consumption did not reduce total cholesterol, LDL-C, HDL-C and triglycerides levels, but increased the concentrations of isobutiric, propionic and isovaleric acids, as well as the total amount of short chained fatty acids in faeces.

Anticarcinogenic Effects

Their antitumorigenic activities have been confirmed by feeding trials on animal models both in cancer and in cultured tumor cells 87. The anticarcinogenic role of fermented dairy products can be attributed, in general, to cancer prevention and the suppression of early-stage tumors, by the delaying of enzyme activities that convert pro-carcinogenic compounds to carcinogens, or by the activation of the immune system 81. Kubo et al. 88 reported the inhibition of the proliferation of subcutaneously transplanted Ehrlich ascites tumors in mice. Liu et al. 51 observed the inhibition of tumor growth, the induction of apoptotic cell lysis in tumors and significant increases in IgA levels in mice, suggesting that kefir potentially has anti-tumoral properties and promotes resistance of the mucosa to intestinal infections. Guven and Gulmez 89 reported that mice treated with kefir had a higher protective effect against damage induced by carbon tetrachloride, indicating that kefir can also act as an antioxidant.

In summary, evidence suggests a beneficial effect of kefir on cancer prevention and treatment. However, further studies are warranted in human subjects to determine whether such protecttive effects are also exerted in the human body.

Stimulation of the Immune System

The formation of bioactive peptides during fermentation or digestion processes has shown a variety of physiological activities, including stimulation of the immune system in animal models 14. Thoreux and Schmucker 90, after feeding mice with kefir, observed an increase in the specific mucosal immune response (IgA) against the cholera toxin. Stimulation of the immune system may also occur due to the action of exopolysaccharides found in kefir grains 14. Medrano et al. 91 observed that kefiran was able to modify the balance of the immune cells in the intestinal mucosa. Vinderola et al. 11 demonstrated the immunomodulation ability of kefir in the immune response of the intestinal mucosa of mice. The administration of kefir also induced a response in the intestinal mucosa, suggesting that components of kefir can stimulate cells of the innate immune system, suppressing the immune response of the Th2 phenotype or promoting cell-mediated immune responses against tumors and intracellular pathogen infections 51. Recently, Hong et al. 92 demonstrated, in vitro, the immunomodulating capacity of LAB isolated from kefir grains, suggesting their influence on the secretion of the proinflammatory cytokines IL-6 and TNF-α by TLR-2.

Anti-inflammatory and Healing Activity

Healing and anti-inflammatory activities of kefir and kefiran in mice were observed after a seven-day treatment with kefir gel 12, as well as anti-inflammatory activitiy 93 on a model in which granulomatous tissue and writhing is induced by acetic acid in mice. Husseini et al. 60 corroborated the healing activity in burns infected with Pseudomonas aeruginosa in mice.

Antimicrobial Activity

Santos et al. 94 observed the antagonistic behavior of lactobacilli isolated from kefir grains against E. coli, L. monocytogenes, Salmonella Typhimurium, S. Enteritidis, Shigella flexneri and Y. enterocolitica. Silva et al. 95 observed the inhibition of Candida albicans, Salmonella Typhi, Shigella sonnei, Staphylococcus aureus and E. coli by kefir cultured in brown sugar. On the other hand, Chifiriuc et al. 96 observed that all milk fermented with kefir grains had antimicrobial activity against Bacillus subtilis, S. aureus, E. coli, E. faecalis and S. Enteritidis, but did not inhibit P. aeruginosa and C. albicans. All these studies indicate that kefir antimicrobial activity is associated with the production of organic acids, peptides (bacteriocins), carbon dioxide, hydrogen peroxide, ethanol and diacetyl. These compounds may have beneficial effects not only in the reduction of food borne pathogens and deteriorating bacteria during beverage production and storage, but also in the treatment and prevention of gastroenteritis and vaginal infections 81. In addition, the antimicrobial activity of the polysaccharide kefiran was also demonstrated against bacteria and C. albicans 12.

Kefir vs Yogurt

Yogurt, yoghurt, or yoghourt is a food produced by lactic acid-producing bacteria, Lactobacillus bulgaricus and Streptococcus thermophilus fermentation of milk 97. The bacteria used to make yogurt are known as “yogurt cultures”. Fermentation of lactose in milk by these bacteria produces lactic acid, which acts on milk protein to give yogurt its texture and characteristic tart flavor 97. Cow’s milk is commonly available worldwide, and, as such, is the milk most commonly used to make yogurt. Milk from water buffalo, goats, ewes, mares, camels, and yaks is also used to produce yogurt where available locally. Milk used may be homogenized or not (milk distributed in many parts of the world is homogenized); both types may be used, with substantially different results.

The word “yogurt” is believed to have come from the Turkish word “yoğurmak,” which means to thicken, coagulate, or curdle 98. While references to the health-promoting properties of yogurt date back to 6000 BC in Indian Ayurvedic scripts, it was not until 1905, when a Bulgarian medical student, Stamen Grigorov, discovered Bacillus bulgaricus (now Lactobacillus bulgaricus), a lactic acid bacteria that is still used in yogurt cultures today. Based on Grigorov’s findings, in 1909, the Russian Nobel laureate, Yllia Metchnikoff, from the Pasteur Institute in Paris, suggested that lactobacilli in yogurt were associated with longevity in the Bulgarian peasant population 99. In the beginning of the 20th century, yogurt became known for its health benefits and was sold in pharmacies as a medicine.

The types of yogurt consumed today are influenced by local traditions or correspond to certain lifestyles. In Eastern Europe and Asia, people consume milk that has undergone alcoholic fermentation by combining bacteria and yeasts (e.g., Kefir, Koumis); in Germany and Spain, yogurt is typically heat-treated to kill the bacteria; and in other countries, various probiotics and/or prebiotics are added to the mix.

Yogurt is produced using a culture of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus bacteria. In addition, other lactobacilli and bifidobacteria are also sometimes added during or after culturing yogurt. Some countries require yogurt to contain a certain amount of colony-forming units of bacteria; in China, for example, the requirement for the number of lactobacillus bacteria is at least 1 × 106 CFU per milliliter 100.

To produce yogurt, milk is first heated, usually to about 85 °C (185 °F), to denature the milk proteins so that they do not form curds. After heating, the milk is allowed to cool to about 45 °C (113 °F) 101. The bacterial culture is mixed in, and a temperature of 45 °C (113 °F) is maintained for four to twelve hours to allow fermentation.

Yogurt (plain yogurt from whole milk) is 81% water, 9% protein, 5% fat, and 4% carbohydrates, including 4% sugars. A 100-gram amount provides 406 kilojoules (97 kcal) of dietary energy. As a proportion of the Daily Value (DV), a serving of yogurt is a rich source of vitamin B12 (31% DV) and riboflavin (23% DV), with moderate content of protein, phosphorus, and selenium (14 to 19% Daily Value).

Although yogurt is often associated with probiotics having positive effects on immune, cardiovascular or metabolic health, high-quality clinical evidence is insufficient to conclude that consuming yogurt lowers risk of diseases or improves health 102.

Yogurt today

Today, yogurt is typically milk that has been fermented and acidified with viable and well-defined bacteria, creating a thickened, often flavored, product with an extended shelf life. You can now find many varieties of yogurt in your dairy aisle, including low-fat yogurt, fat-free yogurt, Greek yogurt, Icelandic style (Skyr), Australian style and others. Since yogurt is made from milk, it contains many of the same nutrients, just in different amounts – especially when it comes to the various styles and brands of yogurt 103. Yogurt contains essential nutrients and is a vehicle for fortification (added probiotics, fibers, vitamins, and minerals). It is also easily modified by sweeteners, fruits, and flavors to affect consistency and aroma. Yogurt can also be produced from rice, soy, or nuts.

- Animal-based Yogurt: Yogurt made from the milk of animals, such as cows, goats, sheep, camels, and buffalo.

- Plant-based or non-dairy yogurt: Yogurt made from soy, coconut, nuts, rice or other plant foods. Note that not all plant-based yogurts undergo fermentation so they may not contain live bacteria. Plant-based yogurts may be lower in protein, calcium, and other nutrients unless they are fortified, so check the Nutrition Facts label if these nutrients are important in your diet.

- Greek yogurt, also called “strained yogurt” or “yogurt cheese”: Yogurt that is strained to remove the whey portion, resulting in a thicker consistency than unstrained yogurt while preserving yogurt’s distinctive, sour taste.

- Probiotic: Refers to foods, beverages, and supplements containing specific strains of live bacteria or microbiota. Food manufacturers may add additional probiotic strains for perceived health benefits. However, the exact amount of probiotics and strain of bacteria that yield a beneficial health effect will vary among individuals and is not well-researched.

- CFUs or colony forming units: The number of living bacteria per gram. This is an indication of how many live bacteria are present in the yogurt at the time of manufacture. Yogurt typically contains at least 1,000,000, or 106 CFUs, which is the minimum needed to display a “Live and Active Cultures” seal on the packaging. This minimum number is the standard provided because it is expected that some bacteria will be destroyed when passing through the digestive tract and exposed to stomach acid. Though food manufacturers often promote the health benefits of multiple strains of bacteria and a high amount of CFUs, with some products offering billions of CFUs, research does not support these claims.

The active cultures in yogurt can help aid in the digestion of lactose. Individuals with lactose intolerance who cannot tolerate dairy products may be able to eat some yogurt because of its lower concentration of lactose. Fermentation by the bacteria breaks down lactose to lactic acid. Another option may be plant-based yogurts, which do not contain lactose. Check the package for the additional benefits provided by your favorite yogurt. These may vary depending on the type of culture in the yogurt.

Table 5. Kefir nutrition facts (made with pasteurized whole milk)

Nutrient | Unit | cup 244 g | Value per 100 g | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approximates | |||||||||||||||||||

| Energy | kcal | 146 | 60 | ||||||||||||||||

| Protein | g | 8.00 | 3.28 | ||||||||||||||||

| Total lipid (fat) | g | 8.00 | 3.28 | ||||||||||||||||

| Carbohydrate, by difference | g | 13.01 | 5.33 | ||||||||||||||||

| Fiber, total dietary | g | 0.0 | 0.0 | ||||||||||||||||

| Sugars, total | g | 13.01 | 5.33 | ||||||||||||||||

| Minerals | |||||||||||||||||||

| Calcium, Ca | mg | 281 | 115 | ||||||||||||||||

| Iron, Fe | mg | 0.00 | 0.00 | ||||||||||||||||

| Sodium, Na | mg | 98 | 40 | ||||||||||||||||

| Vitamins | |||||||||||||||||||

| Vitamin C, total ascorbic acid | mg | 0.0 | 0.0 | ||||||||||||||||

| Vitamin A, IU | IU | 249 | 102 | ||||||||||||||||

| Lipids | |||||||||||||||||||

| Fatty acids, total saturated | g | 5.002 | 2.050 | ||||||||||||||||

| Cholesterol | mg | 24 | 10 | ||||||||||||||||

Ingredients: PASTEURIZED MILK, LACTOCOCCUS LACTIS SUBSP., LEUCONOSTOC SP., STREPTOCOCCUS THERMOPHILUS, LACTOBACILLUS SP THERMOPHILIS, LACTOBACILLUS SP, KEFIR YEAST, KEFIR GRAINS MICROFLORA)

[Source: United States Department of Agriculture Agricultural Research Service 104]Table 6. Yogurt nutrition facts (made with pasteurized whole milk)

Nutrient | Unit | cup 227 g | Value per 100 g | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approximates | |||||||||||||||||||

| Energy | kcal | 170 | 75 | ||||||||||||||||

| Protein | g | 7.99 | 3.52 | ||||||||||||||||

| Total lipid (fat) | g | 8.99 | 3.96 | ||||||||||||||||

| Carbohydrate, by difference | g | 14.01 | 6.17 | ||||||||||||||||

| Fiber, total dietary | g | 0.0 | 0.0 | ||||||||||||||||

| Sugars, total | g | 13.01 | 5.73 | ||||||||||||||||

| Minerals | |||||||||||||||||||

| Calcium, Ca | mg | 300 | 132 | ||||||||||||||||

| Iron, Fe | mg | 0.00 | 0.00 | ||||||||||||||||

| Potassium, K | mg | 400 | 176 | ||||||||||||||||

| Sodium, Na | mg | 125 | 55 | ||||||||||||||||

| Vitamins | |||||||||||||||||||

| Vitamin C, total ascorbic acid | mg | 0.0 | 0.0 | ||||||||||||||||

| Vitamin A, IU | IU | 225 | 99 | ||||||||||||||||

| Lipids | |||||||||||||||||||

| Fatty acids, total saturated | g | 5.993 | 2.640 | ||||||||||||||||

| Fatty acids, total trans | g | 0.000 | 0.000 | ||||||||||||||||

| Cholesterol | mg | 34 | 15 | ||||||||||||||||

Ingredients: CULTURED PASTEURIZED WHOLE MILK, CONTAINS LIVE ACTIVE & PROBIOTIC CULTURES (L.BULGARICUS, L.CASEI, L.ACIDOPHILUS, B.BIFIDUS, S.THERMOPHILUS)

[Source: United States Department of Agriculture Agricultural Research Service 104]Summary

Kefir, the traditional beverage, is now recognized as a potential source of probiotics and molecules with highly interesting healthy properties. In kefir grains the main polysaccharide is kefiran, which is a heteropolysaccharide composed by equal proportions of glucose and galactose and is mainly produced by Lactobacillus kefiranofaciens 24. It has been demonstrated that kefiran improves the viscosity and viscoelastic properties of acid milk gels 25, and is able to form gels that have interesting viscoelastic properties at low temperatures, because of that, kefiran can also be used as an additive in fermented products. Besides, kefiran can enhance the rheological properties of chemically acidified skim milk gels increasing their apparent viscosity 26. In addition to these characteristics, exopolysaccharides that are obtained from microorganisms such as lactic acid bacteria from kefir are classified as GRAS (generally recognized as safe) by the U.S. Food and Drug Administration 66. Compared with other polysaccharides, kefiran has outstanding advantages such as antitumor, antifungal, antibacterial properties, immunomodulation or epithelium protection, anti-inflammatory, healing and antioxidant activity, among other roles. Although the existing scientific studies involving test tubes and animals demonstrated the health benefits of kefir consumption, the evidence is not conclusive and further studies should be conducted on human subjects. The good news is research is constantly being conducted to consolidate kefir and kefiran properties for the development of new important products to preserve consumer’s health.

References- De Oliveira Leite AM, Miguel MAL, Peixoto RS, Rosado AS, Silva JT, Paschoalin VMF. Microbiological, technological and therapeutic properties of kefir: a natural probiotic beverage. Brazilian Journal of Microbiology. 2013;44(2):341-349. doi:10.1590/S1517-83822013000200001. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3833126/

- Magalhães KT, de Melo Pereira GV, Campos CR, Dragone G, Schwan RF. Brazilian kefir: structure, microbial communities and chemical composition. Brazilian Journal of Microbiology. 2011;42(2):693-702. doi:10.1590/S1517-838220110002000034. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3769826/

- Irigoyen A., Arana I., Castiella M., Torre P., Ibáñez F.C. Microbiological, physicochemical, and sensory characteristics of kefir during storage. Food Chem. 2005;90(4):613–620.

- Moreira S.R., Schwan R.F., Carvalho E.P., Wheals A.E. Isolation and identification of yeasts and filamentous fungi from yoghurts in Brazil. Braz. J. Microbio.l. 2001;32(2):117–122.

- Tamime AY. Production of Kefir, Koumiss and Other Related Products. In: Tamime AY, editor. Fermented Milk. Blackwell Science Ltd; Oxford, UK: 2006. pp. 174–216.

- Rattray FP, O’Connell MJ. Fermented Milks Kefir. In: Fukay JW, editor. Encyclopedia of Dairy Sciences. 2th ed. Academic Press; San Diego, USA: 2011. pp. 518–524.

- Farnworth ER, Mainville I. Kefir – A Fermented Milk Product. In: Farnworth ER, editor. Handbook of Fermented Functional Foods. 2th ed. CRC Press Taylor & Francis Group; Boca Raton, London, New York: 2008. pp. 89–127. (2 ed).

- Kefir: a symbiotic yeasts-bacteria community with alleged healthy capabilities. Lopitz-Otsoa F, Rementeria A, Elguezabal N, Garaizar J. Rev Iberoam Micol. 2006 Jun; 23(2):67-74. http://www.reviberoammicol.com/2006-23/067074.pdf

- Otles S., Cagindi O. Kefir: a probiotic dairy-composition, nutritional and therapeutic aspects. Pak. J. Nutr. 2003;2(1):54–59.

- Kefiran antagonizes cytopathic effects of Bacillus cereus extracellular factors. Medrano M, Pérez PF, Abraham AG. Int J Food Microbiol. 2008 Feb 29; 122(1-2):1-7. https://www.ncbi.nlm.nih.gov/pubmed/18174111/

- Immunomodulating capacity of kefir. Vinderola CG, Duarte J, Thangavel D, Perdigón G, Farnworth E, Matar C. J Dairy Res. 2005 May; 72(2):195-202. https://www.ncbi.nlm.nih.gov/pubmed/15909685/

- Antimicrobial and healing activity of kefir and kefiran extract. Rodrigues KL, Caputo LR, Carvalho JC, Evangelista J, Schneedorf JM. Int J Antimicrob Agents. 2005 May; 25(5):404-8. https://www.ncbi.nlm.nih.gov/pubmed/15848295/

- Anti-inflammatory and anti-allergic effects of kefir in a mouse asthma model. Lee MY, Ahn KS, Kwon OK, Kim MJ, Kim MK, Lee IY, Oh SR, Lee HK. Immunobiology. 2007; 212(8):647-54. https://www.ncbi.nlm.nih.gov/pubmed/17869642/

- Farnworth ER. Kefir – a complex probiotic. Food Sci Technol Bull: Functional Foods. 2005;2:1–17.

- Microbial communities and chemical changes during fermentation of sugary Brazilian kefir. Magalhães KT, de M Pereira GV, Dias DR, Schwan RF. World J Microbiol Biotechnol. 2010 Jul; 26(7):1241-50. https://www.ncbi.nlm.nih.gov/pubmed/24026929/

- Güzel-Seydim Z., Wyffels J.T., Seydim A.C., Greene A.K. Turkish kefir and kefir grains: microbial enumeration and electron microscobic observation. Int. J. Dairy Technol. 2005;58(1):25–29.

- Brazilian kefir: structure, microbial communities and chemical composition. Magalhães KT, de Melo Pereira GV, Campos CR, Dragone G, Schwan RF. Braz J Microbiol. 2011 Apr; 42(2):693-702. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3769826/

- Pogačić T., Sinko S., Zamberlin S., Samarzija D. (2013). Microbiota of kefir grains. Mljekarstvo 63 3–14.

- Analysis of the microflora in Tibetan kefir grains using denaturing gradient gel electrophoresis. Zhou J, Liu X, Jiang H, Dong M. Food Microbiol. 2009 Dec; 26(8):770-5. https://www.ncbi.nlm.nih.gov/pubmed/19835760/

- Use of whey lactose from dairy industry for economical kefiran production by Lactobacillus kefiranofaciens in mixed cultures with yeasts. Cheirsilp B, Radchabut S. N Biotechnol. 2011 Oct; 28(6):574-80. https://www.ncbi.nlm.nih.gov/pubmed/21315193/

- Selection of lactic acid bacteria from Brazilian kefir grains for potential use as starter or probiotic cultures. Zanirati DF, Abatemarco M Jr, Sandes SH, Nicoli JR, Nunes ÁC, Neumann E. Anaerobe. 2015 Apr; 32():70-6. https://www.ncbi.nlm.nih.gov/pubmed/25542841/

- Yeasts from kefir grains: isolation, identification, and probiotic characterization. Diosma G, Romanin DE, Rey-Burusco MF, Londero A, Garrote GL. World J Microbiol Biotechnol. 2014 Jan; 30(1):43-53. https://www.ncbi.nlm.nih.gov/pubmed/23824665/

- Garrote GL, Abraham AG, De Antoni G. Microbial Interactions in Kefir: A Natural Probiotic Drink. In: Mozzi F, Raya RR, Vignolo GM, editors. Biotechnology of Lactic Acid Bacteria – Novel Applications. Iowa: Blackwell Publishing; 2010. pp. 327–340.

- Zajšek K., Kolar M., Goršek A. (2011). Characterisation of the exopolysaccharide kefiran produced by lactic acid bacteria entrapped within natural kefir grains. Int. J. Dairy Technol. 64 544–548. 10.1111/j.1471-0307.2011.00704.x

- Rimada P. S., Abraham A. G. (2006). Effects of different fermentation parameters on quality characteristics of kefir. Int. Dairy J. 16 33–39. 10.3168/jds.2012-5753

- Cultivating conditions effects on kefiran production by the mixed culture of lactic acid bacteria imbedded within kefir grains. Zajšek K, Goršek A, Kolar M. Food Chem. 2013 Aug 15; 139(1-4):970-7. https://www.ncbi.nlm.nih.gov/pubmed/23561198/

- Physicochemical properties of exopolysaccharide produced by Lactobacillus kefiranofaciens ZW3 isolated from Tibet kefir. Wang Y, Ahmed Z, Feng W, Li C, Song S. Int J Biol Macromol. 2008 Oct 1; 43(3):283-8. https://www.ncbi.nlm.nih.gov/pubmed/18662712/

- Kefir fermented milk and kefiran promote growth of Bifidobacterium bifidum PRL2010 and modulate its gene expression. Serafini F, Turroni F, Ruas-Madiedo P, Lugli GA, Milani C, Duranti S, Zamboni N, Bottacini F, van Sinderen D, Margolles A, Ventura M. Int J Food Microbiol. 2014 May 16; 178():50-9. https://www.ncbi.nlm.nih.gov/pubmed/24667318/

- Anti-inflammatory properties of kefir and its polysaccharide extract. Rodrigues KL, Carvalho JC, Schneedorf JM. Inflammopharmacology. 2005; 13(5-6):485-92. https://www.ncbi.nlm.nih.gov/pubmed/16280101/

- Chen Z., Shi J., Yang X., Nan B., Liu Y., Wang Z. (2015). Chemical and physical characteristics and antioxidant activities of the exopolysaccharide produced by Tibetan kefir grains during milk fermentation. Int. Dairy J. 43 15–21. 10.1016/j.idairyj.2014.10.004

- Prado MR, Blandón LM, Vandenberghe LPS, et al. Milk kefir: composition, microbial cultures, biological activities, and related products. Frontiers in Microbiology. 2015;6:1177. doi:10.3389/fmicb.2015.01177. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4626640/

- Investigation on culturable microflora in Tibetan kefir grains from different areas of China. Gao J, Gu F, Abdella NH, Ruan H, He G. J Food Sci. 2012 Aug; 77(8):M425-33. https://www.ncbi.nlm.nih.gov/pubmed/22860591/

- A review on traditional Turkish fermented non-alcoholic beverages: microbiota, fermentation process and quality characteristics. Altay F, Karbancıoglu-Güler F, Daskaya-Dikmen C, Heperkan D. Int J Food Microbiol. 2013 Oct 1; 167(1):44-56. https://www.ncbi.nlm.nih.gov/pubmed/23859403/

- Rea MC, Lennartsson T, Dillon P, Drina FD, Reville WJ, Heapes M, Cogan TM. Irish kefir-like grains : their structure, microbial composition and fermentation kinetics. J Appl Microbiol. 1996;8:83–94.

- Kefir: a symbiotic yeasts-bacteria community with alleged healthy capabilities. Lopitz-Otsoa F, Rementeria A, Elguezabal N, Garaizar J. Rev Iberoam Micol. 2006 Jun; 23(2):67-74. https://www.ncbi.nlm.nih.gov/pubmed/16854180/

- Wang S. Y., Chen K. N., Lo Y. M., Chiang M. L., Chen H. C., Liu J. R., et al. (2012). Investigation of microorganisms involved in biosynthesis of the kefir grain. Food Microbiol. 32 274–285. 10.1016/j.fm.2012.07.001. https://www.ncbi.nlm.nih.gov/pubmed/22986190

- Application of culture-dependent and culture-independent methods for the identification of Lactobacillus kefiranofaciens in microbial consortia present in kefir grains. Hamet MF, Londero A, Medrano M, Vercammen E, Van Hoorde K, Garrote GL, Huys G, Vandamme P, Abraham AG. Food Microbiol. 2013 Dec; 36(2):327-34. https://www.ncbi.nlm.nih.gov/pubmed/24010614/

- Öner Z, Karahan AG, Çakmakçi MLE. Effects of different milk types and starter cultures on kefir. Gida. 2010;35:177–182.

- Lactic acid bacteria and yeasts in kefir grains and kefir made from them. Simova E, Beshkova D, Angelov A, Hristozova Ts, Frengova G, Spasov Z. J Ind Microbiol Biotechnol. 2002 Jan; 28(1):1-6. https://www.ncbi.nlm.nih.gov/pubmed/11938463/

- Beshkova D, Simova ED, Simov ZI, Frengova GI, Spasov ZN. Pure cultures for making kefir. Food Microbiol. 2002;19:537–544.

- Assadi MM, Pourahmad R, Moazami N. Use of isolated kefir starter cultures in kefir production. World J Microbiol Biotechnol. 2000;16:541–543.

- Rossi J, Gobbetti M. Impiego di un multistarter per la produzione in continuo di kefir. Vol. 41. Milano, ITALIE: Dipartimento di scienze e tecnologie alimentari e microbiologiche dell’ Universitá degli studi di Milano; 1991.

- Carneiro RP. M.Sc. Dissertation. Belo Horizonte, Brasil: Faculdade de Farmácia. UFMG; 2010. Desenvolvimento de uma cultura iniciadora para produção de kefir; p. 142.

- Paraskevopoulou A, Athanasiadis I, Kanellaki M, Bekatorou A, Blekas G, Kiosseoglou V. Functional properties of single cell protein produced by kefir microflora. Food Res Int. 2003;36:431–438.

- Metagenomic analysis of the microbial community in kefir grains. Nalbantoglu U, Cakar A, Dogan H, Abaci N, Ustek D, Sayood K, Can H. Food Microbiol. 2014 Aug; 41():42-51. https://www.ncbi.nlm.nih.gov/pubmed/24750812/

- Lopitz F. O., Rementeria A., Elguezabal N., Garaizar J. (2006). Kefir: una comunidad simbiótica de bacterias y levaduras con propiedades saludables. Rev. Iberoam. Micol. 23 67–74. 10.1016/S1130-1406(06)70016-X. https://www.ncbi.nlm.nih.gov/pubmed/16854180

- Kefir and health: a contemporary perspective. Ahmed Z, Wang Y, Ahmad A, Khan ST, Nisa M, Ahmad H, Afreen A. Crit Rev Food Sci Nutr. 2013; 53(5):422-34. https://www.ncbi.nlm.nih.gov/pubmed/23391011/

- Probiotic properties of Lactobacillus strains isolated from Tibetan kefir grains. Zheng Y, Lu Y, Wang J, Yang L, Pan C, Huang Y. PLoS One. 2013; 8(7):e69868. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3718794/

- The antiproliferative effect of kefir cell-free fraction on HuT-102 malignant T lymphocytes. Rizk S, Maalouf K, Baydoun E. Clin Lymphoma Myeloma. 2009; 9 Suppl 3():S198-203. https://www.ncbi.nlm.nih.gov/pubmed/19778841/

- Effects of Lactobacillus plantarum MA2 isolated from Tibet kefir on lipid metabolism and intestinal microflora of rats fed on high-cholesterol diet. Wang Y, Xu N, Xi A, Ahmed Z, Zhang B, Bai X. Appl Microbiol Biotechnol. 2009 Aug; 84(2):341-7. https://www.ncbi.nlm.nih.gov/pubmed/19444443/

- Antitumor activity of milk kefir and soy milk kefir in tumor-bearing mice. Liu JR, Wang SY, Lin YY, Lin CW. Nutr Cancer. 2002; 44(2):183-7. https://www.ncbi.nlm.nih.gov/pubmed/12734066/

- Milk kefir: ultrastructure, antimicrobial activity and efficacy on aflatoxin B1 production by Aspergillus flavus. Ismaiel AA, Ghaly MF, El-Naggar AK. Curr Microbiol. 2011 May; 62(5):1602-9. https://www.ncbi.nlm.nih.gov/pubmed/21350802/

- Protective effect of a mixture of kefir-isolated lactic acid bacteria and yeasts in a hamster model of Clostridium difficile infection. Bolla PA, Carasi P, Bolla Mde L, De Antoni GL, Serradell Mde L. Anaerobe. 2013 Jun; 21():28-33. https://www.ncbi.nlm.nih.gov/pubmed/23542116/

- Heterogeneity of S-layer proteins from aggregating and non-aggregating Lactobacillus kefir strains. Mobili P, Serradell Mde L, Trejo SA, Avilés Puigvert FX, Abraham AG, De Antoni GL. Antonie Van Leeuwenhoek. 2009 May; 95(4):363-72. https://www.ncbi.nlm.nih.gov/pubmed/19306111/

- Surface proteins from Lactobacillus kefir antagonize in vitro cytotoxic effect of Clostridium difficile toxins. Carasi P, Trejo FM, Pérez PF, De Antoni GL, Serradell Mde L. Anaerobe. 2012 Feb; 18(1):135-42. https://www.ncbi.nlm.nih.gov/pubmed/22126976/

- Gao J., Gu F., Ruan H., Chen Q., He J., He G. (2013b). Induction of apoptosis of gastric cancer cells SGC7901 in vitro by a cell-free fraction of Tibetan kefir. Int. Dairy J. 30 14–18. 10.1016/j.idairyj.2012.11.011

- Study of anti-inflammatory activity of Tibetan mushroom, a symbiotic culture of bacteria and fungi encapsulated into a polysaccharide matrix. Diniz RO, Garla LK, Schneedorf JM, Carvalho JC. Pharmacol Res. 2003 Jan; 47(1):49-52. https://www.ncbi.nlm.nih.gov/pubmed/12526861/

- Hong W. S., Chen H. C., Chen Y. P., Chen M. J. (2009). Effects of kefir supernatant and lactic acid bacteria isolated from kefir grain on cytokine production by macrophage. Int. Dairy J. 19 244–251. 10.1016/j.idairyj.2008.10.010

- The antiallergic effect of kefir Lactobacilli. Hong WS, Chen YP, Chen MJ. J Food Sci. 2010 Oct; 75(8):H244-53. https://www.ncbi.nlm.nih.gov/pubmed/21535502/

- Evaluation of wound healing activities of kefir products. Huseini HF, Rahimzadeh G, Fazeli MR, Mehrazma M, Salehi M. Burns. 2012 Aug; 38(5):719-23. https://www.ncbi.nlm.nih.gov/pubmed/22237053/

- Young-In K., Apostolidis E., Shetty K. (2006). Anti-diabetes functionality of kefir culture-mediated fermented soymilk supplemented with Rhodiola extracts. Food Biotechnol. 20 13–29. 10.1080/08905430500522055

- Guzel-Seydim Z. B., Seydim A. C., Greene A. K., Ta T. (2006). Determination of antimutagenic properties of acetone extracted fermented milks and changes in their total fatty acid profiles including conjugated linoleic acids. Int. J. Dairy Technol. 59 209–215. 10.1111/j.1471-0307.2006.00265.x

- Antigenotoxic effect of kefir and ayran supernatants on fecal water-induced DNA damage in human colon cells. Grishina A, Kulikova I, Alieva L, Dodson A, Rowland I, Jin J. Nutr Cancer. 2011; 63(1):73-9. https://www.ncbi.nlm.nih.gov/pubmed/21161824/

- Kefir exhibits anti‑proliferative and pro‑apoptotic effects on colon adenocarcinoma cells with no significant effects on cell migration and invasion. Khoury N, El-Hayek S, Tarras O, El-Sabban M, El-Sibai M, Rizk S. Int J Oncol. 2014 Nov; 45(5):2117-27. https://www.ncbi.nlm.nih.gov/pubmed/25189203/

- Kefir administration reduced progression of renal injury in STZ-diabetic rats by lowering oxidative stress. Punaro GR, Maciel FR, Rodrigues AM, Rogero MM, Bogsan CS, Oliveira MN, Ihara SS, Araujo SR, Sanches TR, Andrade LC, Higa EM. Nitric Oxide. 2014 Feb 15; 37():53-60. https://www.ncbi.nlm.nih.gov/pubmed/24406684/

- New perspectives for Lactobacilli exopolysaccharides. Badel S, Bernardi T, Michaud P. Biotechnol Adv. 2011 Jan-Feb; 29(1):54-66. https://www.ncbi.nlm.nih.gov/pubmed/20807563/

- Wang Y. P., Li C., Liu P., Zaheer A., Xiao P., Bai X. (2010). Physical characterization of exopolysaccharide produced by Lactobacillus plantarum KF5 isolated from Tibet Kefir. Carbohydr. Polym. 82 895–903. 10.1016/j.carbpol.2010.06.013

- Saija N., Welman A., Bennett R. (2010). Development of a dairy-based exopolysaccharide bioingredient. Int. Dairy J. 20 603–608. 10.1016/j.idairyj.2010.03.011

- Kim Y., Kim J. U., Oh S., Kim Y. J., Kim M., Kim S. H. (2008). Technical optimization of culture conditions for the production of exopolysaccharide (EPS) by Lactobacillus rhamnosus ATCC 9595. Food Sci. Biotechnol. 17 587–593.

- Piermaria J., Bosch A., Pinotti A., Yantorno O., Garcia M. A., Abraham A. G. (2010). Kefiran films plasticized with sugars and polyols: water vapor barrier and mechanical properties in relation to their microstructure analyzed by ATR/FT-IR spectroscopy. Food Hydrocoll. 25 1261–1269. 10.1016/j.foodhyd.2010.11.024

- Kooiman P. (1968). The chemical structure of kefiran, the water-soluble polysaccharide of the kefir grain. Carbohydr. Res. 7 220–221. 10.1016/S0008-6215(00)81138-6

- Witthuhn R. C., Schoeman T., Britz T. J. (2005). Characterisation of the microbial population at different stages of kefir production and kefir grain mass cultivation. Int. Dairy J. 15 383–389. 10.1016/j.idairyj.2004.07.016

- Enhanced kefiran production by mixed culture of Lactobacillus kefiranofaciens and Saccharomyces cerevisiae. Cheirsilp B, Shimizu H, Shioya S. J Biotechnol. 2003 Jan 9; 100(1):43-53. https://www.ncbi.nlm.nih.gov/pubmed/12413785/

- Structure-function relationships of glucansucrase and fructansucrase enzymes from lactic acid bacteria. van Hijum SA, Kralj S, Ozimek LK, Dijkhuizen L, van Geel-Schutten IG. Microbiol Mol Biol Rev. 2006 Mar; 70(1):157-76. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1393251/

- Ruas-Madiedo P., Hugenholtz J., Zoon P. (2002). An overview of the functionality of exopolysaccharides produced by lacti acid bacteria. Int. Dairy J. 12 163–171. 10.1016/S0958-6946(01)00160-1

- Exopolysaccharides from lactic acid bacteria: perspectives and challenges. Welman AD, Maddox IS. Trends Biotechnol. 2003 Jun; 21(6):269-74. https://www.ncbi.nlm.nih.gov/pubmed/12788547/

- Heteropolysaccharides from lactic acid bacteria. De Vuyst L, Degeest B. FEMS Microbiol Rev. 1999 Apr; 23(2):153-77. https://www.ncbi.nlm.nih.gov/pubmed/10234843/

- Zhang B., Xu N., Xi A. D., Wang Y. P. (2009). Screening and identification of cholesterol-reducing KF5 strain. J. Tianjin Univ. Sci. Technol. 24 17–20.

- Dietary influence of kefir on microbial activities in the mouse bowel. Marquina D, Santos A, Corpas I, Muñoz J, Zazo J, Peinado JM. Lett Appl Microbiol. 2002; 35(2):136-40. https://www.ncbi.nlm.nih.gov/pubmed/12100589/

- Zacconi C, Scolari G, Vescovo M, Sarra PG. Competitive exclusion of Campyloacter jejuni by kefir fermented milk. Ann Microbiol. 2003;53:179–187.

- Sarkar S. Potential of kefir as a dietetic beverage – a review. Br Food J. 2007;109:280–290.

- De Vrese, M., Keller, B., and Barth, C. A. (1992). Enhancement of intestinal hydrolysis of lactose by microbial β-galactosidase (EC 3.2.1.23) of kefir. Br. J. Nutr. 67:67–75.

- Hertzler, S. R., and Clancy, S. M. (2003). Kefir improves lactose digestion and tolerance in adults with lactose maldigestion. J. Am. Diet. Assoc. 103:582–587.

- Enhancement of intestinal hydrolysis of lactose by microbial beta-galactosidase (EC 3.2.1.23) of kefir. de Vrese M, Keller B, Barth CA. Br J Nutr. 1992 Jan; 67(1):67-75. https://www.ncbi.nlm.nih.gov/pubmed/1547204/

- Hypocholesterolaemic effects of milk-kefir and soyamilk-kefir in cholesterol-fed hamsters. Liu JR, Wang SY, Chen MJ, Chen HL, Yueh PY, Lin CW. Br J Nutr. 2006 May; 95(5):939-46. https://www.ncbi.nlm.nih.gov/pubmed/16611384/

- Kefir consumption does not alter plasma lipid levels or cholesterol fractional synthesis rates relative to milk in hyperlipidemic men: a randomized controlled trial [ISRCTN10820810]. St-Onge MP, Farnworth ER, Savard T, Chabot D, Mafu A, Jones PJ. BMC Complement Altern Med. 2002; 2():1. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC65674/

- Svensson, M., Sabharwal, H., Mossberg, A. K., Lipniunas, P., Leffler, H., Svanborg, C., and Linse, S. (1999). Molecular characterization of alphalactalbumin folding variants that induce apoptosis in tumor cells. J. Biol. Chem. 274:6388–6396.

- [Pharmacological study on kefir–a fermented milk product in Caucasus. I. On antitumor activity (1)]. Kubo M, Odani T, Nakamura S, Tokumaru S, Matsuda H. Yakugaku Zasshi. 1992 Jul; 112(7):489-95. https://www.ncbi.nlm.nih.gov/pubmed/1432599/

- The effect of kefir on the activities of GSH-Px, GST, CAT, GSH and LPO levels in carbon tetrachloride-induced mice tissues. Güven A, Güven A, Gülmez M. J Vet Med B Infect Dis Vet Public Health. 2003 Oct; 50(8):412-6. https://www.ncbi.nlm.nih.gov/pubmed/14633213/

- Kefir milk enhances intestinal immunity in young but not old rats. Thoreux K, Schmucker DL. J Nutr. 2001 Mar; 131(3):807-12. https://www.ncbi.nlm.nih.gov/pubmed/11238763/

- Oral administration of kefiran induces changes in the balance of immune cells in a murine model. Medrano M, Racedo SM, Rolny IS, Abraham AG, Pérez PF. J Agric Food Chem. 2011 May 25; 59(10):5299-304. https://www.ncbi.nlm.nih.gov/pubmed/21504180/

- Hong WS, Chen HC, Chen YP, Chen MJ. Effects of kefir supernatant and lactic acid bacteria isolated from kefir grain on cytokine production by macrophage. Int Dairy J. 2009;19:244–251.

- Diniz RO, Perazzo FF, Carvalho JCT, Schneenedorf JM. Atividade antiinflamatória de quefir, um probiótico da medicina popular. Rev Bras Farmacogn. 2003;13:19–21.

- The antimicrobial properties of different strains of Lactobacillus spp. isolated from kefir. Santos A, San Mauro M, Sanchez A, Torres JM, Marquina D. Syst Appl Microbiol. 2003 Sep; 26(3):434-7. https://www.ncbi.nlm.nih.gov/pubmed/14529186/

- Antimicrobial activity of broth fermented with kefir grains. Silva KR, Rodrigues SA, Filho LX, Lima AS. Appl Biochem Biotechnol. 2009 Feb; 152(2):316-25. https://www.ncbi.nlm.nih.gov/pubmed/18663417/

- In vitro assay of the antimicrobial activity of kephir against bacterial and fungal strains. Chifiriuc MC, Cioaca AB, Lazar V. Anaerobe. 2011 Dec; 17(6):433-5. https://www.ncbi.nlm.nih.gov/pubmed/21624484/

- “Yogurt: from Part 131 — Milk and Cream. Subpart B–Requirements for Specific Standardized Milk and Cream, Sec. 131.200” U.S. Food and Drug Administration. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=131.200

- History of yogurt and current patterns of consumption. Nutrition Reviews, Volume 73, Issue suppl_1, 1 August 2015, Pages 4–7, https://doi.org/10.1093/nutrit/nuv020. https://academic.oup.com/nutritionreviews/article-lookup/doi/10.1093/nutrit/nuv020

- McGee H. Fresh fermented milks and creams. In: Dorfman P Greene J McGee A, eds. Food and Cooking: The Science and Lore of the Kitchen . New York: Scribner; 2004; 44–51.

- Lee, Yuan Kee et al. (2012) “Probiotic Regulation in Asian Countries”. In Lahtinen, Sampo et al. (Eds.) (2012). Lactic Acid Bacteria: Microbiological and Functional Aspects, Fourth Edition. Boca Raton: CRC Press. ISBN 9780824753320. page 712.

- Chandan, Ramesh C.; Kilara, Arun (22 December 2010). Dairy Ingredients for Food Processing. John Wiley & Sons. pp. 1–. ISBN 978-0-470-95912-1.

- Health benefits and health claims of probiotics: bridging science and marketing. British Journal of Nutrition, Volume 106, Issue 9, September 2017 , pp. 1291-1296. https://www.cambridge.org/core/journals/british-journal-of-nutrition/article/health-benefits-and-health-claims-of-probiotics-bridging-science-and-marketing/3C143B002B0289188B006FACA906E3BE/core-reader

- https://dairygood.org/content/2016/what-is-yogurt

- United States Department of Agriculture Agricultural Research Service. USDA Branded Food Products Database. https://ndb.nal.usda.gov/ndb/search/list